Multi disc screw press dewatering for waste water treatment in

dairy factory SS304

Direct dewatering the oxidation ditch

The Sludge Dewatering Press is an enclosed high performance sludge

dewatering system. It utilizes a central screw auger and a slowly

oscillating multi-disk filter to gradually increase pressure on

flocculated sludge to produce an exceptionally dry sludge cake.

With electrical, water and polymer usage, and high capture rates

the system is very cost effective.

The Sludge Dewatering Press can be provided with all equipment

required for dewatering included and factory mounted, piped and

wired on a single stainless steel skid. This equipment includes the

sludge pump, wash water pump, polymer dosing system and control

panel. The system features fully automated one pushbutton startup

and shutdown. Once started up the system can run unattended and can

be set to shutdown automatically with no operator intervention.

Application

- Sewage and waste water treatment plants of municipal water

- Waste water treatment plant in agricultrual & fishery community

- Industrial waste water treatment plants

- Effluent treatment plant in food & beverage production plants

- Dairy farming / meat processing plants

- Chemicals manufacturing plants

- Machinery manufacturing plants

- Laundry wastewater treatment

- Paper & pulp, building material manufacturing, oilfield associated

waste water containing crude oil mining.

Technical introduction

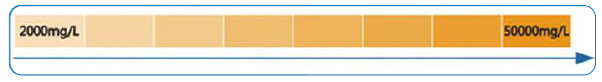

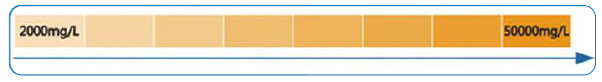

The volute is structured with a filter element that consists of two

type rings: a fixed ring and a moving ring; and a screw that

thrusts the filter element and transfers and pressurizes the

sludge. The gaps between the rings and the screw pitch are designed

to gradually get narrower towards the direction of sludge cake

outlet and inner pressure of the filter element increases due to

the volume compression effect, which thicknens and dewaters the

sludge.

Features:

- The dewatering body is formed by a screw axis with fixing and

moving plates overlapping, as the inner diameter of screw axis is

larger than the moving plate, the moving plate do the circular

motion with the screw axis to prevent clogging, to ensure the

continuous operation

- Municipal wastewater, papermaking wastewater, chemical waste water,

food and beverage processing waste water, industrial wastewater,

papermaking wastewater, pharmaceutical wastewater, oil processing

and mining wastewater, etc.

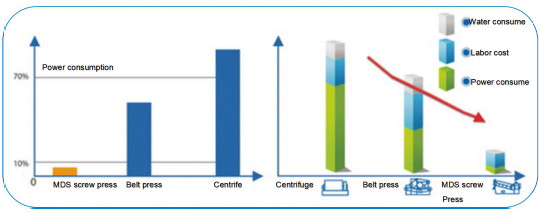

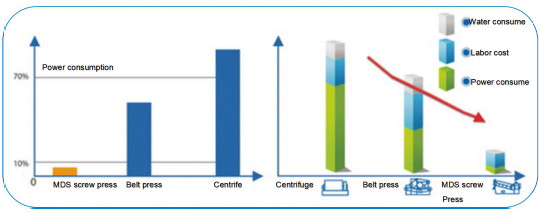

- Comparing with the traditional belt, plate& frame and centrifugal

machine,volute sludge dewatering machine adopts integrated design

of dehydration ontology, flocculation mixing tank and electric

control device, convenient installation , small area cover, strong

compatibility with ancillary equipment, greatly reduce design and

the construction cost, at the same time, no need to undertake civil

construction as its exquisite design.

- Can realise 24 hours automatic unmanned operation by PLC remote

control , reduce the operating personnel employment and maintenance

costs. At the same time, due to the exquisite design, easy

operation, it is easy to learn as no special knowledge and skilled

technical complex requirements.

- Main body can self-cleaning due to the special structure, threr is

no need to use a lot of water for cleaning to prevent clogging.

Compared with the same capacity of dewatering machine, screw rinse

water consumption is only 1% of belt . The rotation speed of screw

shaft is 2-5 turn/min , low power consumption. Power consumption is

only 5% of the centrifuge, at the same time, no noise during

operation as slow rotation speed and intermittent flush.

Sludge treatment process:

Flow diagram

Layout

Specification

| Model | DS treatment capacity(DS.KG/H) | Slurry Flow rate (M³/h) |

| 10000mg/l | 20000mg/l | 25000mg/l | 50000mg/l |

| (low concentration) | (High concentration) |

| KTDL131 | 5 | 10 | 0.5 | 0.5 | 0.4 | 0.2 |

| KTDL132 | 10 | 20 | 1 | 1 | 0.8 | 0.4 |

| KTDL251 | 15 | 30 | 1.5 | 1.5 | 1.2 | 0.6 |

| KTDL252 | 30 | 60 | 3 | 3 | 2.4 | 1.2 |

| KTDL301 | 30 | 60 | 3 | 3 | 2.4 | 1.2 |

| KTDL302 | 60 | 120 | 6 | 6 | 4.8 | 2.4 |

| KTDL303 | 90 | 180 | 9 | 9 | 7.2 | 3.6 |

| KTDL304 | 120 | 240 | 12 | 12 | 9.6 | 4.8 |

| KTDL351 | 50 | 100 | 5 | 5 | 4 | 2 |

| KTDL352 | 100 | 200 | 10 | 10 | 8 | 4 |

| KTDL353 | 150 | 300 | 15 | 15 | 12 | 6 |

| KTDL354 | 200 | 400 | 20 | 20 | 16 | 8 |

| KTDL401 | 80 | 160 | 8 | 8 | 6.4 | 3.2 |

| KTDL402 | 160 | 320 | 16 | 16 | 12.8 | 6.4 |

| KTDL403 | 240 | 480 | 24 | 24 | 19.2 | 9.6 |

| KTDL404 | 320 | 640 | 32 | 32 | 25.6 | 12.8 |

Advantages

- Direct dewatering from oxidation ditch

- Contactless structure, less worn out

- Minimal initial investment

Options

The Sludge Dewatering Press offers a completely operational, skid

mounted and self-contained system which can include:

• Screw Press

• PLC Controls

• Sludge Pumps

• Back Wash System

• Flocculation System

• Polymer Dosing Unit

• Sludge Cake Conveyor

Production line

Applications

| Municipal sewage | petro refining | leather making | printing and dyeing paper | paper & pulp |

| coalification dressing | biochemical | pharmacy | steel pickling | chemicals |

| sugar | food processing | food & beverage | mining | sludge treatment |

Competitive advantage

Multi-Disk Screw Press is a cutting edge sludge dewatering

equipment with non-clogging design and low energy consumption,

especially applicable for oily sludge.