FS Membrane bioreactor for waste water treatment in soybean paste

factory 150 m3/day

MBR introduction

The membrane bioractor are widely used in effluent and sewage

treatment plant. It can purify domestic and industrial wastewater

by combining the action of microorganisms with the separation of

solids from liquids using membranes. The membrane removes suspended

solids and pathogenic e-coli bacteria, so that the effluent water

can be re-used as toilet flushing water or sprinkling water

The MBR membrane bioreactor removes not only suspended solids (SS)

but also substances difficult to biodegrade such as detergent, by

taking advantage of its longer Sludge Retention Time (SRT). This

enables the treated water to be re-used.

Specifications

| Model of FS | 150 | 80 | 25 | 10 |

| Effective membrane area (m2) | 1.5 | 0.8 | 0.25 | 0.1 |

| Size L*W*T (mm) | 490*1750*7 | 490*1000*7 | 340*470*7 | 220*320*6 |

| Weight (kg) | 5.5 | 3.2 | 0.8 | 0.4 |

| Pore size (µm) | <0.10 | | | |

| Membrane material | PVDF | | | |

| Flux (L/pc.day) | 600 - 800 | 320 - 480 | 100 - 150 | 40 - 60 |

| Aeration capacity (L/pc.min) | >12 | >12 | >9 | >6 |

| PH range | 3 - 12 |

| Outlet effluent turbidity (NTU) | <0.1 |

| Outlet effluent SS (mg/L) | <5 |

Above datas are tested at standard single sheet FS MBR with

municipal waste water at 25 ℃ and operation pressure 10Kpa.

Key features

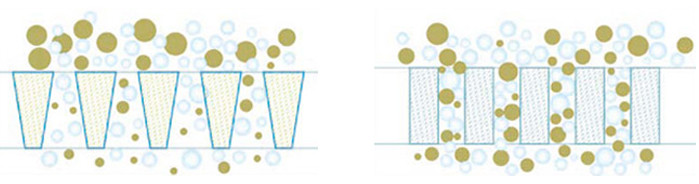

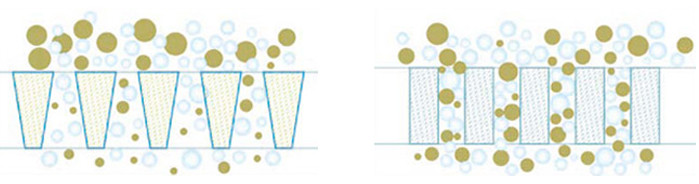

- The excellent chemical stability, fouling resistance and mechanical

strength

- The pore size is less than 0.1 micron, the improved effective

membrane area ensures large permeate flux and quality

- The perfect fouling resistance due to the asymmetric structure.

This features low membrane resistance, good fouling resistance.

large particles from rosion of air, won't enter into the membrane.

The small particles through the membrane, won't be stranded in the

membrane pore and quickly flow through the large hole out of the

membrane

- The FS MBR can be with higher concentration of activated sludge

(MLSS is larger than 8000 mg / L). Mebrane surface area doesn't

plot the mude and no lose of effective membrane area. Air and water

erosion on the membrane surface remove the membrane surface dirty

- The FS membrane is firmly welded on high-intensity support plate,

it does not appear the phenomenon of broken wires as hollow fiber

so permeate water quality stable. This is very important for the

waste water treatment application followed by NF / RO membrane

recycle process.

Asymmetric structure for fouling resistance

Asymmetric structure Symmetric structure

Comparison between flat sheet membrane and hollow fiber membrane

Easily clean and membrane replacement

Specifications of modular

<

| Model | MBR element | Nos of MBR | Membrane area | Capacity | Max capacity | net weight | Air supply |

| (piece) | (m2) | (m3/day) | (m3/day) | (kg) | (L/min) |

| 80-50 | S80 | 50 | 40 | 20 | 40 | 340 | 600 |

| 80-60 | 60 | 48 | 24 | 48 | 380 | 720 |

| 80-80 | 80 | 64 | 32 | 64 | 470 | 960 |

| 80-100 | 100 | 80 | 40 | 80 | 560 | 1200 |

| 80-120 | 120 | 96 | 48 | 96 | 660 | 1440 |

| 80-140 | 140 | 112 | 56 | 112 | 770 | 1680 |

| 80-150 | 150 | 120 | 60 | 120 | 830 | 1800 |

| 80-160 | 160 | 128 | 64 | 128 | 900 | 1920 |

| 80-200 | 200 | 160 | 80 | 160 | 1140 | 2400 |

| 150-50 | S150 | 50 | 75 | 37.5 | 75 | 420 | 600 |

| 150-60 | 60 | 90 | 45 | 90 | 520 | 720 |

| 150-80 | 80 | 120 | 60 | 120 | 670 | 960 |

| 150-100 | 100 | 150 | 75 | 150 | 730 | 1200 |

| 150-120 | 120 | 180 | 90 | 180 | 890 | 1440 |

| 150-140 | 140 | 210 | 105 | 210 | 1050 | 1680 |

| 150-150 | 150 | 225 | 112.5 | 225 | 1140 | 1800 |

| 150-160 | 160 | 240 | 120 | 240 | 1230 | 1920 |

| 150-200 | 200 | 300 | 150 | 300 | 1550 | 2400 |

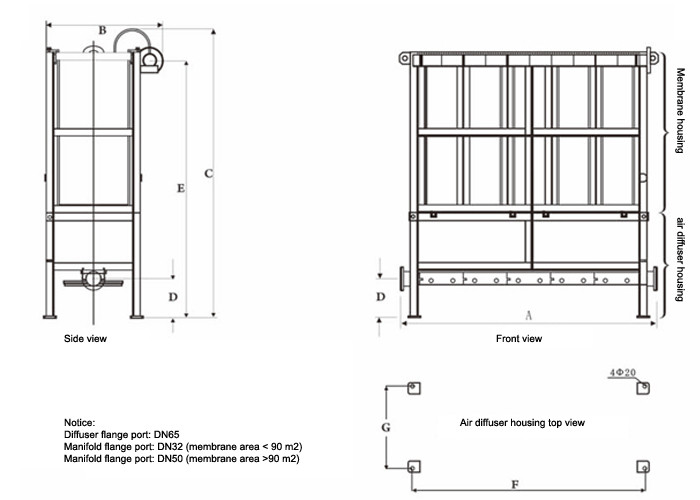

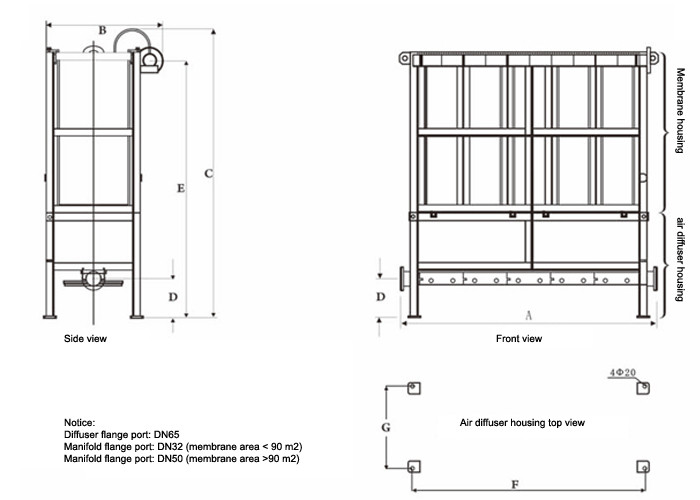

Dimensions

| Model | MBR element | Membrane area

(m2) | Capacity

(m3/day) | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) |

|

| 80-50 | S80 | 40 | 16 - 24 | 965 | 720 | 1850 | 240 | 1695 |

| 80-60 | | 48 | 19 - 28 | 1090 |

| 80-80 | | 64 | 25 - 38 | 1385 |

| 80-100 | | 80 | 32 - 48 | 1670 | 755 | 1693 |

| 80-120 | | 96 | 38 - 57 | 1950 |

| 80-140 | | 112 | 44 - 67 | 2230 |

| 80-150 | | 120 | 48 - 72 | 2375 |

| 80-160 | | 128 | 51 - 76 | 2530 |

| 80-200 | | 160 | 64 - 96 | 3100 |

| 150-50 | S150 | 75 | 30 - 45 | 965 | 720 | 2600 | 240 | 2445 |

| 150-60 | | 90 | 36 - 54 | 1090 |

| 150-80 | | 120 | 48 - 72 | 1385 | 755 | 2443 |

| 150-100 | | 150 | 60 - 90 | 1670 |

| 150-120 | | 180 | 72 - 108 | 1950 |

| 150-140 | | 210 | 84 - 126 | 2230 |

| 150-150 | | 225 | 90 - 135 | 2375 |

| 150-160 | | 240 | 96 - 144 | 2530 |

| 150-200 | | 300 | 120 - 180 | 3100 |

Applications

Emulsified oil waste water Hospital waste water Scenic spot sewage

landfill leachate wafter grinding waste water woolen waste water

dairy, food & beverage pharmaceutical heat sanitizable

whey plants concentration WPI plants Gelatine

Sugar